GIBPOMPE – PUMP AND TRANSFER SYSTEM FOR THE FOOD INDUSTRY

PATENTED GIBPOMPE PIPE TRANSFER OF AGRO-FOOD PRODUCTS

Patented GIBPOMPE food product transfer system

The GIBPOMPE has been developed specifically for sensitive and breatable products. Combining piston pump and air-push technology, it guarantees a smooth transfer while minimizing water consumption ( 10% only for the more complex product).

We have the answers to your needs :

- Transport of products and co-products

- Biosafety requirements

- Long distances to be covered

- Reduced water consumption

- CIP: High-pressure cleaning in-place

- Elimination of handling accidents

- Low-pressure transfer for delicate products

- Short-term return on investment

Specifically for delicate materials:

- Soft materials.

- Liquid materials.

- Viscous materials.

- Gelatinous materials.

- Delicate / sensitive materials.

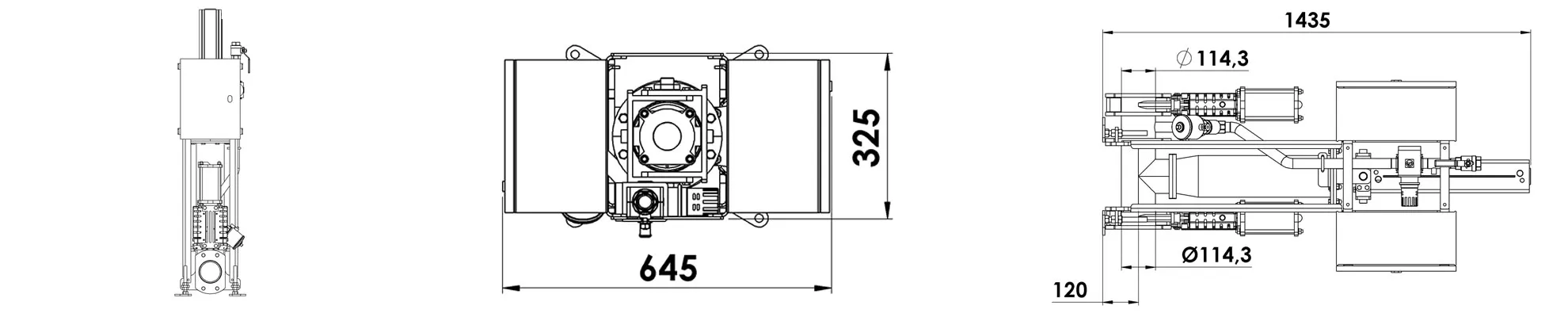

GIBPOMPE TECHNICAL SHEET

| GIBPOMPE PRODUCT | |

|---|---|

| Hygiene, safety, reliability. Automatic cleaning. Compressed air 6 bars minimum. |  |

| GIBPOMPE | |

| Ejection capacity | 0.5 to 5 m³ / h (1) |

| Electric tension | 400 V-Three + Earth 4 A Min |

| Cleaning in place (CIP - CIP) | Optional |

| Pre-equipped box | Yes |

| soundproof | - |

| Dimensions (W x H x D) in mm | 300 x 1100 x 800 |

| Distance and height (with intermediate trigger) | ∞ |

| Application examples | |

| Chicken, turkey, duck | Viscera, neck, liver / heart / gizzard |

| Powder, granulated | - |

| Cattle | - |

| Hog | - |

| Fish | Bone, head, viscera, whole fish |

GIBPOMPE PROCESS VIDEOS – TRANSFER OF DELICATE PRODUCTS

OUR CUSTOMER REFERENCES