OTHER GMMI PRODUCTS – INDUSTRIAL EQUIPMENT DESIGN

DESIGN OF INDUSTRIAL EQUIPMENT BY GMMI

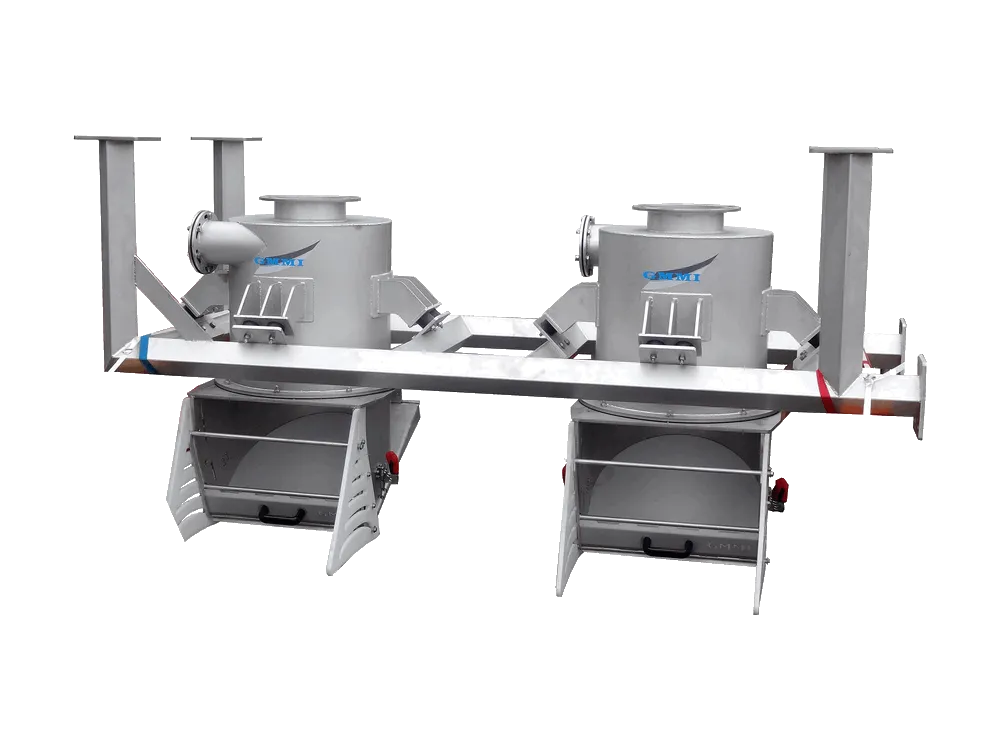

SCREEN

Our screen is designed in accordance with IAA standards, it allows upstream or downstream of the transfer to separate the water from the product.

Downstream, it makes it possible to have less pneumatic transport cycles, thus saving on consumption.

The water filtered and separated from its product is uncharged, therefore cleaner water to be treated for the station.

The screen is used to separate and filter the water from the product. The recovered water is less loaded and therefore faster treatment in the station.

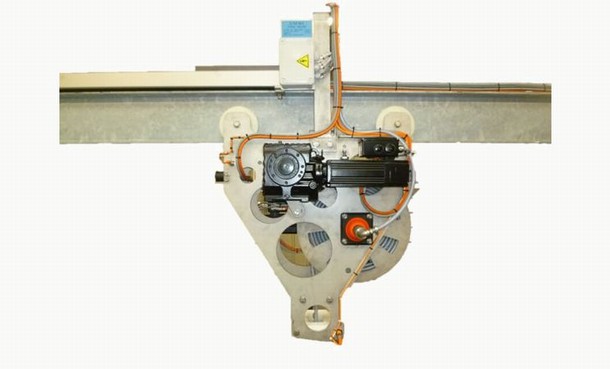

LIQUID SEPARATOR CHARGED (SOLID / LIQUID)

The separator has been specially designed for the pressing of food products such as eggs (and shells) and fruits, it is also suitable for the separation of loaded liquids, treatment sludge, contaminated water or any liquid / solid separation.

Description

- Product separation by compression

- Recovery of liquid and dry matter separately

- Archimedean screw system

- Filtration by custom-made 316L stainless steel drum

- Heavy-gauge, mechanically welded 304L stainless steel pressing head

- Gear motor

- IP65 enclosure

- Weight: 250kg

Technical solution

- Stainless steel design for use in the food industry

- No clogging of the filter

- Easy cleaning based on disassembly without tools

- Different filter models to adapt to the products to be treated

- Very silent

LEATHER AND SKINS PROCESSING LINE

Technical solution

- Salting winch (handling of skins)

- Removes the charging port

- Facilitates the spreading of skins on pallets

- Stacking of skins by additional level program

- Salt booster (salting of the skins)

- Fully automated and secure

- Adjustable projection lance

- Double filtration of salt clods before spraying

- 1200 Liter buffer storage hopper with rotary devourer

- Skin turner (folding of the skins)

- Additional salt recovery

- Flip the leather

- Facilitates the folding station